What is A2L

Understanding A2L Refrigerants: Essential Tools for Modern HVAC Systems

As the industry shifts towards more environmentally friendly solutions, A2L refrigerants are leading the way. Learn how these mildy flammable refrigerants are changing the landscape of HVAC systems and why they’re crucial for the future of refrigeration.

The Air Conditioning and Refrigeration industry in the US is phasing out the use of higher Global Warming Potential (GWP) refrigerants beginning in 2022, which will necessitate different refrigerants with lower GWP ratings. Most, if not all, of these refrigerants will have an ASHRAE safety classification of A2L.

Frequently Asked Questions about the Next Generation of Refrigerants and the A2L Classification

Why are we changing to new refrigerants (again, for some of us) in the US?

The passage of the American Innovation and Manufacturing (AIM) Act (2020), and the US Senate's ratification of the Kigali Amendment (2022) to the Montreal Protocol, directed the EPA to promulgate and enforce rules to reduce HFC refrigerant consumption. This has led to the use of a new class of refrigerants known as Hydroflouroolefin (HFO), which are often blended with HFC R-32 to make a lower GWP blend.

Are HFC refrigerants being phased out entirely like CFC and HCFC refrigerants?

No. HFC refrigerants are being phased down to minimal levels starting in 2022 when the allocations will be capped at 90% of previous levels, and reach the lowest level of production in 2036.

Can A2L classified refrigerants directly replace refrigerants classified as A1?

No. Even though the possibility of an A2L refrigerant igniting is very low, the equipment must be designed and rated for A2L refrigerants for safety reasons.

Are A2L Refrigerants Flammable?

A2L refrigerants are in a newer classification on the lower part of the Lower Flammability scale of the ASHRAE 34 standard that is often referred to as "mildly flammable". This designation means that flame propagation occurs at a flame velocity of less than 10 cm/second (3.9 in/second). The low flame speed means that combustion of an A2L gas does not sustain after the ignition source is removed. For reference, R-290 (Propane) has a burning velocity of around 46 cm/second (18.1 in/second) with a much higher heat of combustion than an A2L.

Are A2L refrigerants Propane based?

No. A2L refrigerants are not Propane based. Most of them are classified as an HFO blend, which means they are a blend of an HFO refrigerant (to achieve a lower Global Warming Potential or GWP) and an HFC refrigerant (to get desired performance over the intended operating temperature range).

Are special tools required to service equipment using refrigerants classified as A2L?

Yes, in some situations. Because the new refrigerants have a small chance of ignition, new standards have been developed for tools and equipment intended to work around refrigerants that have flammability classifications.

How long have A2L refrigerants been used?

R-32 has been around for many years, it is half of the components in R-410A. R-1234yf was developed to meet regulations in Europe requiring vehicles to use a refrigerant with less than 150 GWP, has been in use around the world since the early 2010's, and has a GWP of less than 1.

What refrigerants will be used in the future?

Any refrigerants put into systems in the United States must be on the EPA Significant New Alternatives Policy (SNAP) list, which can be found HERE. Currently there are two different low GWP refrigerants that manufacturers of unitary space conditioning equipment have chosen to move forward with; R-32 and R-454B.

Does TruTech Tools decide if tools are acceptable for use near flammable refrigerants?

No. TruTech Tools relies on our manufacturer partners to design, test and rate their tools to the applicable standards that need to be met for the industry. You can see a recording of a webinar from Underwriters Laboratories HERE about the ratings and testing on equipment and tools used near A2L refrigerants.

Upgrade Your HVAC Toolkit with A2L-Compatible Tools

A2L refrigerants are the future of HVAC systems. Ensure your equipment is compatible with the latest standards. Browse our collection of certified tools designed for A2L refrigerants and take your work to the next level.

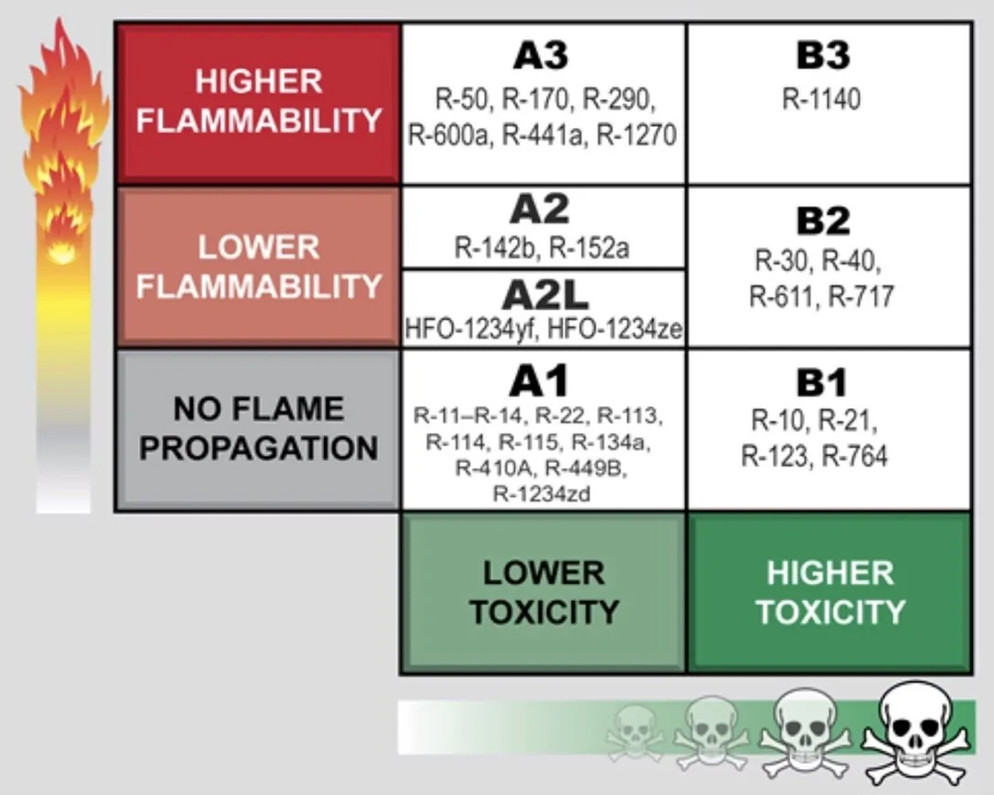

The A2L classification is new, so the misunderstanding it often gets is understandable. When we look at the ASHRAE safety classification chart, we see there are two columns and four rows. The columns indicate toxicity of the refrigerant (lower on the left and higher on the right), and the rows indicate flammability level (No Flame Propagation on the bottom to Higher Flammability on the top). While all refrigerants create inherent danger to operators from potential suffocation if they release large amounts and displace enough oxygen in the area, there are a few that are deemed Toxic and given a "B" classification (one example is R-717 or Ammonia, which is a B2L refrigerant).

Primarily because the 2L classification is new, there is a lot of confusion about what "Mildly Flammable" means. After all, stuff either burns or it doesn't…right? In this case, no. Gasses have levels of flammability, which are measured in Burning Velocity, Heat of Combustion (HOC). To be classified as an 2L the burning velocity must be less than 10 cm/second (3.9 inches/second), and an HOC of less than 8,169 BTU/lb of fuel. To put this into perspective let's look at two common A3 classified refrigerants, R-290 (Propane) and R-600a (Isobutane). Both have burning velocities over 40 cm/second (18.1 inches/second) and their HOC is over 19,000 BTU/lb of fuel. The slower velocity and lower BTU/lb means that during testing flame would not sustain once the ignition source was removed. Another difference between a 2L and 3 flammability classification is the Minimum Ignition Energy (MIE), which is the energy required to ignite an air fuel mixture, and is measured in Millijoules (mj). Current 2L classified refrigerants have an MIE between 30-10,000 mj to ignite (depending on which refrigerant is used), whereas refrigerants R-290 and R-600a require an MIE of 0.25-0.7 mj of energy to ignite. If you would like to dig deep on the subject of what it takes to ignite an A2L refrigerant, this 2018 study from Dennis Kim and Peter Sunderland at the University of Maryland, Department of Fire Protection Engineering, is a good resource.

Does this mean that the only changes will be the actual refrigerant in systems? Unfortunately the answer to that is no. There will be several other changes to installation and service practices. The good news is that if best practices are already being applied to installation and service, the changes necessary should be relatively minor. If best practices are not currently being followed, we recommend getting solid training before working or installing equipment using an A2L refrigerant. A great training manual for flammable and mildly flammable refrigerants comes from ESCO Institute and author Jason Obrzut, CSME.

Changes to Tools and Practices

Changes to tools and practices will be happening as the transition to low GWP refrigerants occurs. This section highlights some of the major changes in a generic manner. Some of these will be manufacturer specific, so make sure to ask equipment suppliers about manufacturer specific training as well.

Refrigerant Recovery Cylinders

- Will be identified by a red band or stripe

- Will likely have left hand threads on the tank connections

- Otherwise will be the same pressure and DOT type as existing recovery tanks

- Evacuation of empty tanks prior to filling with refrigerant is mandatory to make sure no oxygen is mixed with a flammable refrigerant in a compressed environment

Disposable Refrigerant Cylinders

- Will be identified with a red band or stripe

- Will have a resetting pressure relief valve instead of the single use rupture disc style that is currently used

- Needs to be punctured with a non-sparking punch when empty

Tools that should have a rating for A2L or A3 refrigerants, or be non-sparking

- Vacuum pump

- Recovery machine

- Electronic refrigerant leak detector

- Electronic hand tools must be non-sparking

Electrical Components & Compartments

- Are specified and designed to meet standards that keep any leaking refrigerant from coming into contact with a potential ignition source

- This could be done with intrinsically safe (sealed) components, or standard components could be in a sealed or spark arrestor compartment

- Make sure that any gaskets on compartments are in good shape and doors fit tightly as designs

- If components are intrinsically safe, replace only with equally rated components

- This may require going back to the OEM in some cases

Equipment Installation and Service

- There will be a relationship between the total refrigerant charge amount in the system and the indoor volume of the connected structure that needs to be calculated and recorded

- Records of things like leak test, evacuation level, installer, company, and total refrigerant charge will be required

- Depending on the charge amount and the structure volume, leak mitigation and sensor systems may be required

- Purging of the refrigerant circuit with nitrogen immediately after recovery is complete is required

- This is especially important if a torch will be applied to any old lines that might contain traces of a flammable refrigerant

- Pressurized leak testing is required

- Anti nail strike plates will be required by most codes for any refrigerant lines run inside walls

- It will typically be required to prove there are nail plates on any existing line set before it can be reused

- System evacuation is required to keep oxygen from being mixed with a flammable gas under pressure

Jobsite Safety

- An evaluation of the work area should be done for any potential ignition sources prior to working on systems with any sort of flammable refrigerant

- Marking off a working area prior to starting any work is a good idea

- Assessing the ventilation of any working area to keep refrigerant fumes from accumulating is a good idea

- Fire extinguisher(s) should be present anytime a refrigerant system is accessed

- This is one of those requirements that is a best practice, but many of us don't

Transportation and Storage

- Cylinders should be transported in a secure upright position so that pressure relief valves are in contact with only gaseous refrigerant

- Refrigerant manufacturers recommend that disposable tanks be left in the original cardboard sleeve due to identification markings

- Trucks may require flammable placards if the transported volume is high enough

- Sensor systems coupled with active mitigation systems may be required for amounts stored indoors

Recent Posts

-

250 Episodes of HVAC and Building Science (December 2025)

250 Episodes of Building HVAC Science: What We've Learned About Buildings, Comfort, …26th Dec 2025 -

TruTech Tools Leadership Transitions to Support Continued Growth

TruTech Tools Leadership Transitions to Support Continued Growth …4th Dec 2025 -

ESCO Top 25 HVAC Instructors 2026 – Nominations | TruTech Tools

Nominate an HVAC Instructor for the 2026 ESCO "Most Influential HVACR …22nd Oct 2025